Preparing Tin for Collodion

Tin Prep for Collodion

The first thing to keep in mind regarding collodion photography is that as much as we'd all like it to be as fool proof and reliable as roll film, it just isn't. Precoated aluminum is made to suit industrial and architectural applications - NOT photography. As photographers, we've just commandeered its use for tin typing because it's fast, convenient, and easy to use. Your alternative is to shoot ambrotypes on glass (which are beautiful in their own right, but also come with their own set of technical problems!)

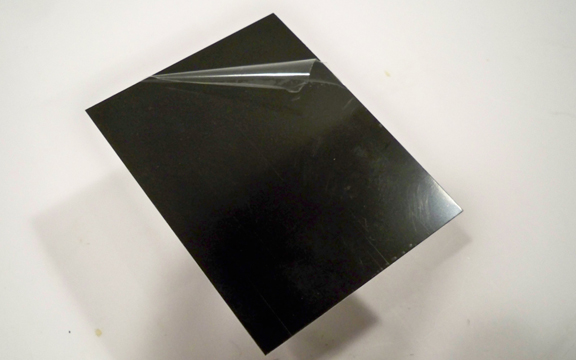

Precoated tin is covered with a protective layer of static cling plastic. This must be removed before applying collodion to the plate. This protective layer is not unlike plastic wrap found in your kitchen drawer. Because it's held in place by static electricity, there are no adhesives to contaminate the coating. You may see mottled marks on the surface of the plate when you remove the protective covering, but this will have no effect on the development of your image.

You may occasionally encounter a "regular" pattern of streaks or spots in a developed image that are aligned along one axis of the plate. This type of artifact is the result of a complex interaction between the collodion, developer, and the coating on the aluminum plate. It is a telltale indication that the plate has been over developed. Overdevelopment occura when:

- development times are too long

- when developer concentration is too high

- or when developer temperatures are too high

The more consistency you have in your process, the fewer problems you'll encounter.

Over development also causes a host of other image problems (increased grain and general muddiness in the shadow areas are the most noticeable) and should be avoided.

To avoid these problems:

- Shoot test plates to determine proper exposure.

- Experiment a little bit to determine the upper and lower limits on your development times for the materials you're using, then choose a medium value for the development time.

- Maintain a fixed and consistent development time (15 seconds is a good value, use a metronome for consistency).